Home > What We Produce > Al-Melting & Holding Furnace

Al-Melting & Holding Furnace

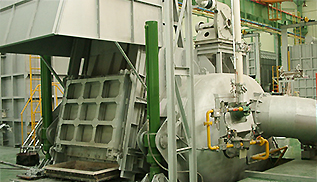

This equipment is an installation that can be used in 30 ton(CH) holding furnace.

Holding furnace is composed of tilting type using hydraulic cylinder, and designed of a structure to attach electronic agitator.

Besides, this is an installation that was fabricated of a structure to attach electronic agitator for smooth melting and that can fabricate melt of excellent product by maximizing efficiency of work through connecting casting speed and melting quantity with caster side via adopting a casting method of tilting type using hydraulic cylinder.

Holding furnace controller has an advantage to enhance quality and save gas by making casting speed controlled accurately and making melt temperature checked at all time through communication with caster.

Besides, this is provided with a self diagnosis system to judge any trouble on its own and inform worker of it.

Holding furnace is composed of tilting type using hydraulic cylinder, and designed of a structure to attach electronic agitator.

The concept is as follows:

This is a system to automatically control the temperature of surroundings inside the furnace and the temperature of melts as a process of making an alloy of raw material ingot and other materials and then melting it, and to maximize thermal efficiency of furnace through adjusting the furnace inside pressure control device and the damper.Besides, this is an installation that was fabricated of a structure to attach electronic agitator for smooth melting and that can fabricate melt of excellent product by maximizing efficiency of work through connecting casting speed and melting quantity with caster side via adopting a casting method of tilting type using hydraulic cylinder.

Holding furnace controller has an advantage to enhance quality and save gas by making casting speed controlled accurately and making melt temperature checked at all time through communication with caster.

Besides, this is provided with a self diagnosis system to judge any trouble on its own and inform worker of it.

Features:

Construction : Tilting method by using the hydraulic cylinderPossible EMS installation

High furnace-efficiency

Automatic temperature control

Linkage adjustment between casting speed and temperature

Furnace internal pressure control device

Damper Recuperator