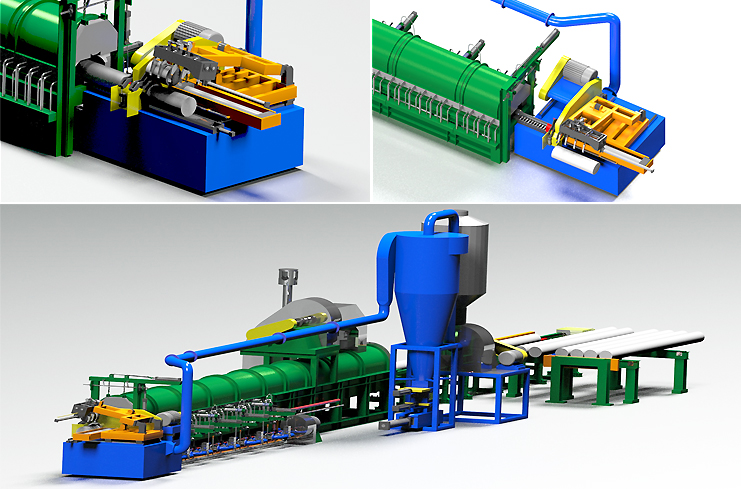

Home > What We Produce > Al-Billet Hot Saw Heating Furnace

Al-Billet Hot Saw Heating Furnace

Hot Saw is an ideal way to help maximize the efficiency of your extrusion system. The Hot Saw allows you to cut every billet to the precise size required just before it enters the press cycle, providing some obvious benefits:

The Hot Saw eliminates the need to stock billets of multiple lengths.

With the Hot Saw, there’s no chance of having a furnace full of the wrong-sized pre-cut billets after a line problem or miscalculation.

The Hot Saw’s electronic control utilizes real-time production information to determine billet length.

Delivering perfect square cuts, so two-piece billets can be used in most cases with no effect on profile quality. (Unlike billets cut with a shear, with the Hot Saw there are no gaps or deformities to trap air and cause potential problems during extrusion.)

The HotSaw has a unique compensation cut feature allows the Hot Saw to “plan ahead” by cutting and storing a billet segment momentarily to avoid winding up with end-of-log pieces that are too short for extrusion, and thus become scrap.

The Hot Saw eliminates the need to stock billets of multiple lengths.

With the Hot Saw, there’s no chance of having a furnace full of the wrong-sized pre-cut billets after a line problem or miscalculation.

The Hot Saw’s electronic control utilizes real-time production information to determine billet length.

Delivering perfect square cuts, so two-piece billets can be used in most cases with no effect on profile quality. (Unlike billets cut with a shear, with the Hot Saw there are no gaps or deformities to trap air and cause potential problems during extrusion.)

The HotSaw has a unique compensation cut feature allows the Hot Saw to “plan ahead” by cutting and storing a billet segment momentarily to avoid winding up with end-of-log pieces that are too short for extrusion, and thus become scrap.

Outline of the facility:

This is a facility that puts long billets to heater, heats them up, cuts them with hot saw into the sizes suitable to each product and transmits them to extruding machine.This is an energy-saving facility because billets are heated directly by fire so that they get heated very rapidly, and a hot-jet fan inhales the exhaust (waste) gas and jets the gas strongly to the billets in the pre-heating zone for pre-heating.

This facility consists of:

Heater system, hot saw system, chip press & collector, pusher system, transfer and control system.

Graphic Photo